There was a bit of a mad rush before Hayley arrived to get all of our designs coherently together and mounted in a way that look professional - we also tidied up the studio. When Hayley arrived, she was very happy to be there - she adored our designs, and even looked a little teary when we gave her the baby Simba to show her students. It was incredibly reassuring that she was so happy with where we'd got at that point on the project. This spurred everyone on to work really hard - immediately after the meeting we sat down and worked out who wanted to do each element of the project.

|

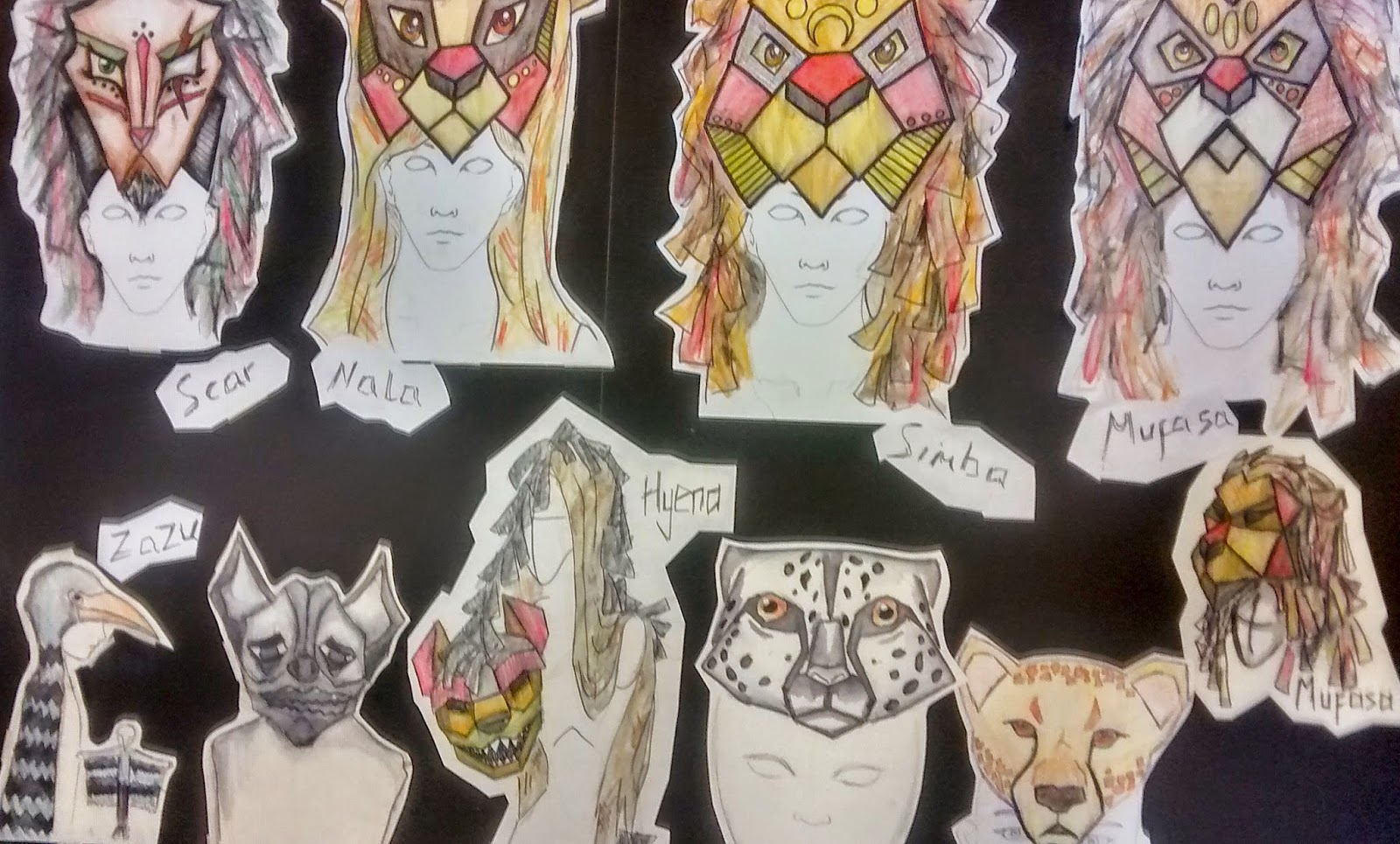

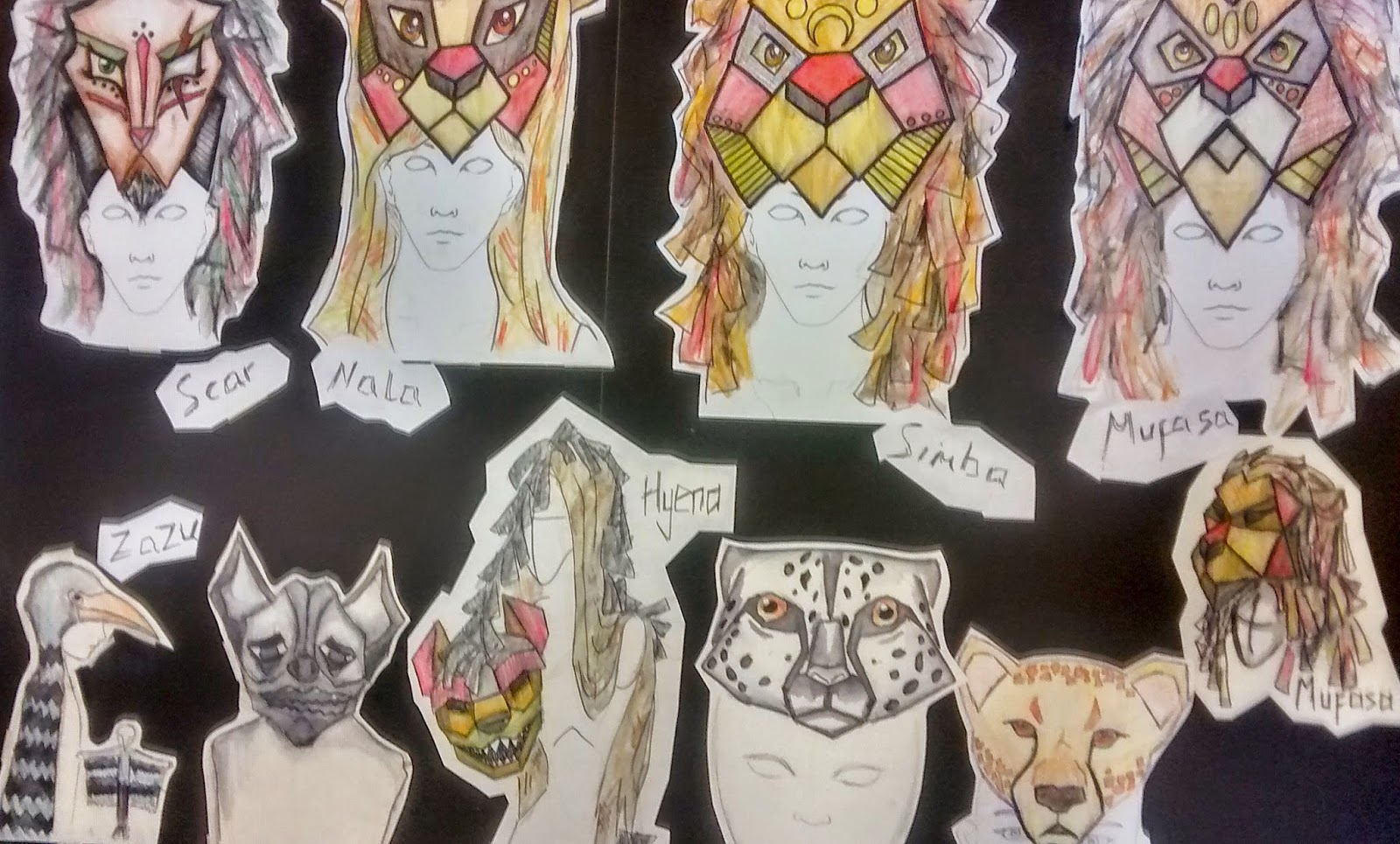

Excuse the poor quality photos - my designs include Mufasa,

Simba, Nala, a hyena and the zebra. |

Jasmine: Simba, zebras, leading hyenas, leading elephant.

Amy: Mufasa, giant Mufasa, costume/fabrics, elephant, Zazu.

Claire: Scar, costume/fabrics, hyenas, elephant.

Becca: Leading Pumba, giraffes, elephant.

Oliver: Pumba, giraffes, cheetahs.

Rhian: Timon, leading cheetahs, elephant.

Tasmin: Leading zebras, antelopes, cheetahs, elephant.

Shona: Leading antelopes, zebras, elephant.

Kristina: Zebras, antelopes, giraffes, elephant.

Lorraine: Costume/fabrics, cheetahs, Timon, elephant.

Esmé: Elephant, hyenas.

Naomi: Leading costume/fabrics.

Melissa: Leading giant Mufasa, elephant, antelopes, hyenas.

Connor: Leading bird kites, costume/fabrics, elephant.

Andrea: Nala, leading Zazu, hyenas, elephant.

The next step is to start refining the process of making the masks. We have toyed with materials a lot - the possibilities as of current stand at layered gum tape, gum tape over a cardboard structure, rhenoflex and possibly vacuum formed plastic for some of the simpler mask shapes.

Whilst gum tape and cardboard would be cheap, I'm not sure if we will be able to make it sturdy enough for use by children yet. Rhenoflex would be great, but it is quite expensive - the budget will have to be revised and considered.

Here is my first design for the elephant, which I sketched out initially whilst we were watching the girls performing it at MidKent.

|

The first drawing I did for this project, before we even had the brief - a one person giraffe. Sadly benign as a design

with the news that the giraffe will be a person with a child on their shoulders, therefore they will not have any

hands free. Certainly a challenge for the group to design! |